|

Cixi Membrane Switch Factory

|

front panels wit 3M back adhesive

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

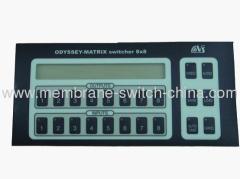

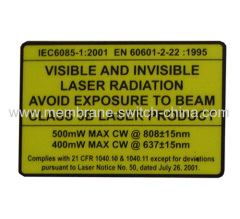

1. Embossed or flat buttons graphic overlay

2. Screen printing

3.Matt or glossy finish

4. UV resistance

5.Custom design

Front panels

Overlay Materials: The most commonly used base materials for graphic overlay are polyester and polycarbonate.

Rear Adhesive: 3M 467MP, 3M 468MP, etc.

Standard Tolerances: +/-.010 inch.

Matching color: Pantone and RAL color matching system.

Environmental

- Storage Temperature: -40°C (-40°F) to +70°C (158°F).

- Storage Altitude: Sea level to 35,000 feet.

- Operating Temperature and Altitude: -30°C (-30°F) to +75°C (170°F). Can be designed to operate in most environments.

- Humidity: No delamination after 24 hours at 80°C and 90%RH.

Graphic Overlay Material Selection

The two most widely used graphic materials are polycarbonate and polyester. polycarbonate comes in thicknesses of 0.127 – 0.762mm thick while polyester comes in thicknesses of 0.127 – 0.254mm.

Polyester has greater tensile strength than does polycarbonate, which often allows it to withstand millions of actuations before fracturing. Also, polyester has a greater resistance to a broad range of chemicals.

Polycarbonate is slightly easier to both print and emboss.

Graphic Design and Preparation

Blueprints – Provide drawings that clearly dimension all physical characteristics including color breaks and copy.

Colors – Identify colors by using Pantone (PMS) color number or a color sample. It is important to supply the exact standard for which our color match will be evaluated.

Background – Dark backgrounds and light text will provide greater clarity and show less wear and dirt.

Artwork – It is possible for customers to supply useable artwork.

Borders and Outlines – Avoid outlines close to cutouts or outer edges.

Text – Block lettering provides the most legible copy. Try to use common fonts. When logos or symbols are used, it is best to supply film positives or accurate black and white artwork .

Products show :

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

.jpg)

.jpg)

.jpg)

.jpg)