|

Cixi Membrane Switch Factory

|

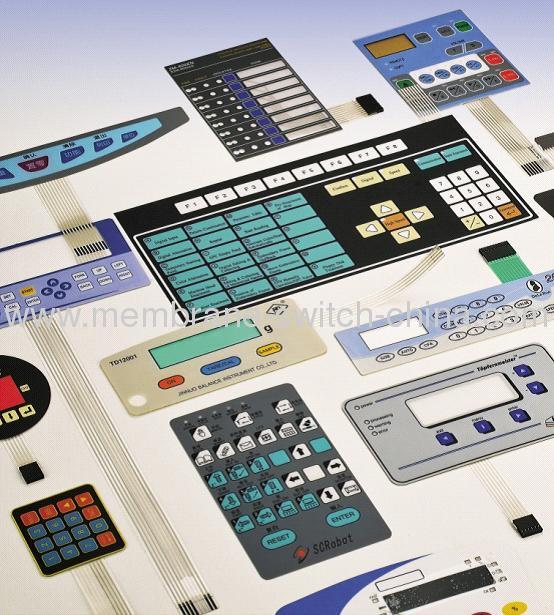

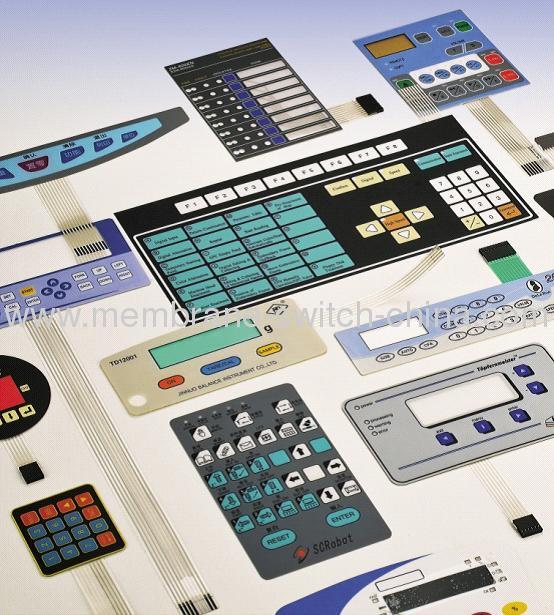

LCD membrane switch panel

| Price: | 0.5~5.0 USD |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Membrane switch with LCD windows are produced using gloss, hard coated, scratch resistant polyester or polycarbonate.

1.Custom design

2.Waterproof

LCD window membrane switch panels

· Membrane switch with LCD windows are produced using gloss, hard coated, scratch resistant polyester or polycarbonate.

· Membrane switch with LCD windows are produced using gloss, hard coated, scratch resistant polyester or polycarbonate.

· Colors and window tints are 2nd surface printed .

· The top surface is usually selectively textured using special inks in the areas where the LCD is not.

· The LCD windows can be specified with alternative gloss levels ,or with a window tint.

· The adhesive or spacer is selectively applied to the back of the overlay so as not to obscure the LCD viewing area, and to avoid the accumulation of debris.

· Dead front windows are possible

LCD window membrane switch panels

Feature:

l Clear or colorful LCD window membrane switch

l Second surface screen printing.

l Fog or glossy surface finish

l Waterproof and UV resistance

l With metal dome or poly dome

Overlay Materials: The most commonly used base materials are polyester and polycarbonate.

Rear Adhesive: 3M 467MP, 3M 468MP, etc.

Standard Tolerances: +/-.010 inch.

Matching color: Pantone and RAL color matching system.

Tail, pin and circuit layout: subject to customers detailed requests.

Notice: We have the capacity to provide you membrane switches with other special requirements, such as Shielding, Windows/Lens Coating, Embossing, Embedded LED, UV glossy/matte/textured, etc.

Electrical

· Operating Voltage: 0-35 V DC.

· Operating Current: 100 MA Max.

· Operating Contact Resistance: Less than 100 OHMS typical

· Contact Bounce: Less than 5 Milliseconds typical.

· Conductors: Printed silver conductive inks or carbon blend.

Mechanical

· Life Expectancy: 1,000,000 actuations per switch position

· Actuation Force:170-700g, Range depending on customer specification.

· Switch Travel: .0.1mm-0.4mm typical.

· Overall Thickness: .0.6mm-1.52mm typical.

Environmental

· Storage Temperature: -40°C to +65°C

· Operating Temperature and Altitude: -40°C to +65°C

· Humidity: No delamination after 24 hours at 80°C and 90%RH.

LCD window membrane switch panels

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Membrane Switch

Membrane Panel

Keyboard Membrane Switch

Custom Membrane Switch

Pcb Membrane Switch

Membrane Keyboard Switch

More>>